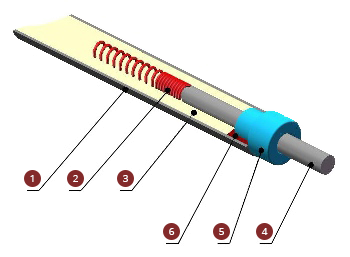

The tubular heating elements are manufactured according to KANTHAL – OAKLEY technology, utilizing the latest patents and solutions from CSM and Kanthal/Granlund machines and equipment. High longevity and reliability are ensured by the use of high-quality materials: magnesium oxide, premium resistance wires, and protective tubes in accordance with the specified standards for the heating industry. Our electric heating elements meet the requirements of DIN EN 60335-1 (VDE -700-1), and are certified for CE and VDE marking.

Nominal voltage and power rating

The voltage range used: 12V…480V.

Typical voltages used: 24V, 48V, 115V, 230V, 400V, 440V.

The power rating of the heating element is selected individually based on the operating conditions and length.

Power tolerance according to DIN EN 60335-1 standard is +5% to -10%. Upon special request, tolerance of ±5% is available.

Standard lengths of dead zones: 40 / 60 / 80 / 100 / 120 / 150 / 180 / 200 … 1000mm.

Heater element tube lengths:

| Material of the protective tube | Heater element diameter | ||||

|---|---|---|---|---|---|

| 6,4mm | 8,5mm | 10mm | 12mm | 16mm | |

| Stainless steel | 200-3350 | 200-4900 | 250-5200 | 250-5200 | 250-6000 |

Tolerance of heater element diameter:

Tolerance of heater element length:

Table of used materials:

| EN | AISI | Max. operating temperature of the material |

|---|---|---|

| 1.4301 | 304 | 450°C |

| 1.4541 | 321 | 550°C |

| 1.4404 | 316L | 450°C |

| 1.4571 | 316Ti | 500°C |

| 1.4828 | 309 | 950°C |

| 1.4876 | Incoloy 800 | 1050°C |

| 2.4858 | Incoloy 825 | 1100°C |

Selection and application of tubular heating elements:

When selecting a heating element, it is necessary to define the following parameters:

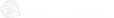

When selecting power, it is necessary to consider the permissible maximum loads depending on the operating conditions:

| Operating Environment | Material | |

|---|---|---|

| AISI 316L, 316Ti, 321 | Incoloy 800, 825 | |

| Stagnant water | 10 | |

| Moving water | 14 | |

| Flowing water | 25 | |

| Steam generators | 6 | |

| Thin oil | 3,5 | |

| Thick oil | 1,2 | |

| Still air | 5 | 6 |

| Moving air v=3m/s | 6 | 7 |

| Moving air v-9m/s | 9 | 9 |

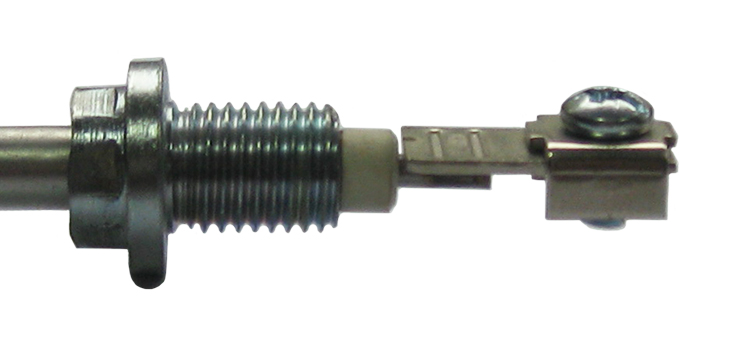

Mounting of Heating Elements:

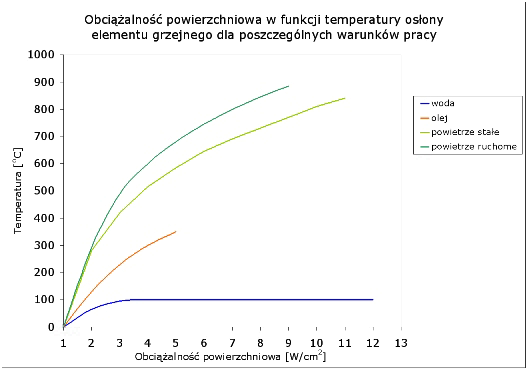

To install a single tubular heating element, we use mounting sleeves that ensure a secure and safe installation in the working environment.

Currently, there are over a hundred different types of mounting sleeves available. We also produce custom mountings specifically tailored to customer orders.

| Mounting Sleeves | |

|---|---|

| Material | Plain galvanized steel, brass, AISI 303, AISI 304 |

| Thread | M10, M12, M14, M16, M18, M20, M22, M24 |

| Mounting Method | Clamping, Hard soldering |

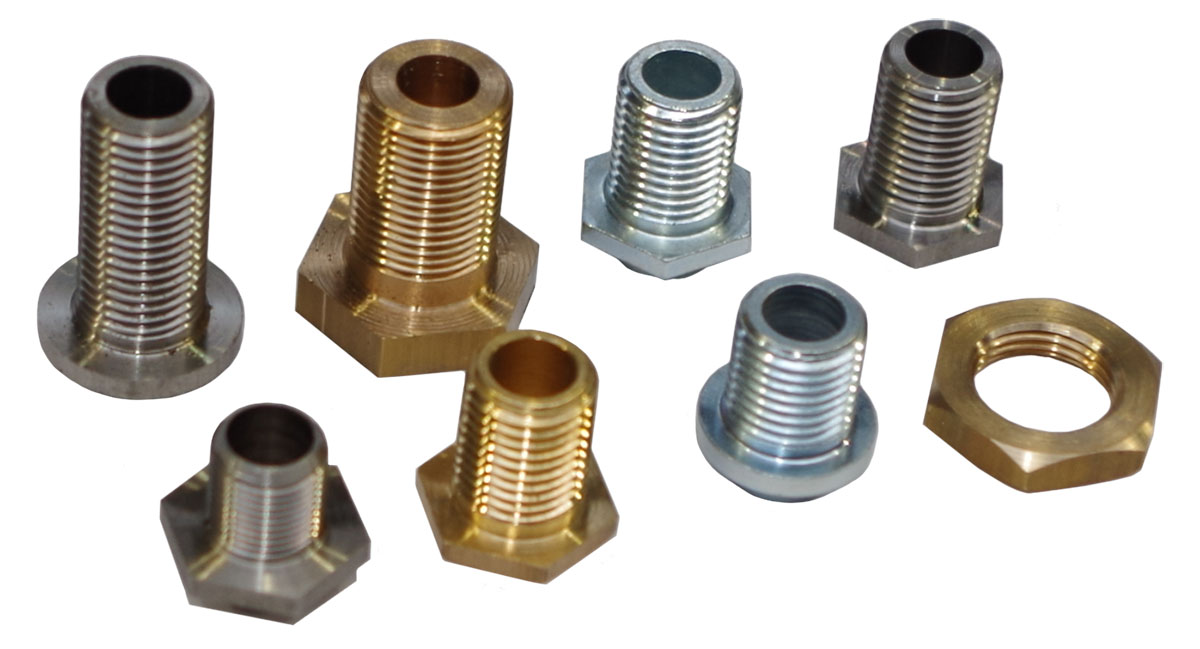

When mounting several individual heating elements close together, we typically use heads/collars with a specified thread.

These heads/collars provide easier installation and better functionality (e.g., electrical connections).

| Mounting Heads / Collars | |

|---|---|

| Material | Brass, stainless steel AISI 304, AISI 316L (available upon request), plain steel ST |

| Thread | G1″ – G2 1/2″ |

| Mounting Method | Hard soldering 45Ag (56Ag available upon request) |

Depending on the size of the head/collar, it is possible to mount up to 6 individual heating elements at once.

An additional mounting method for heating elements includes special mounting plates, round flanges (Dmax=500mm), rectangular flanges (max. 600x400mm), square flanges (max. 400x400mm), protective tubes, etc., all custom-made upon request.

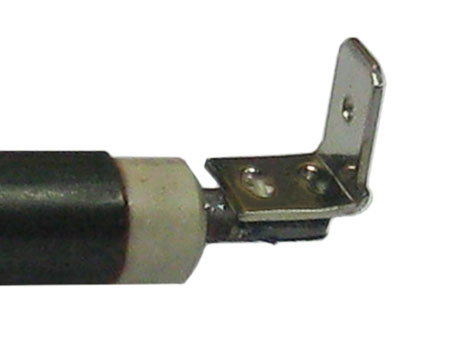

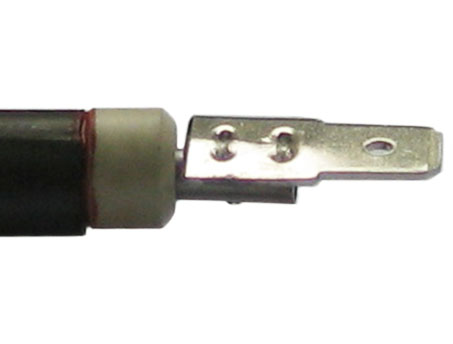

Electrical Terminals:

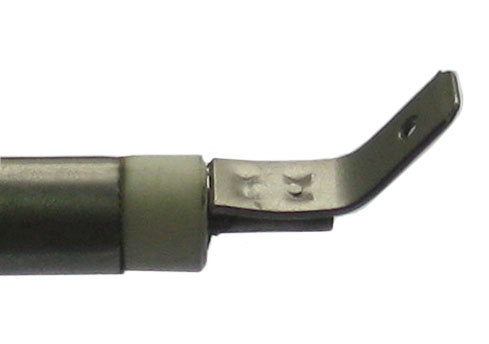

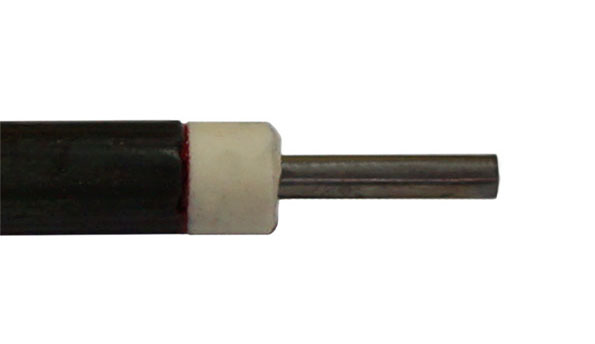

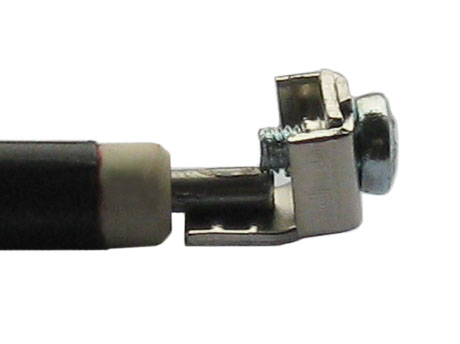

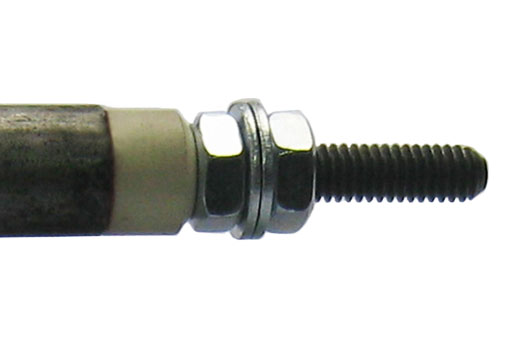

For tubular heating elements, the following electrical terminals are used: