Description:

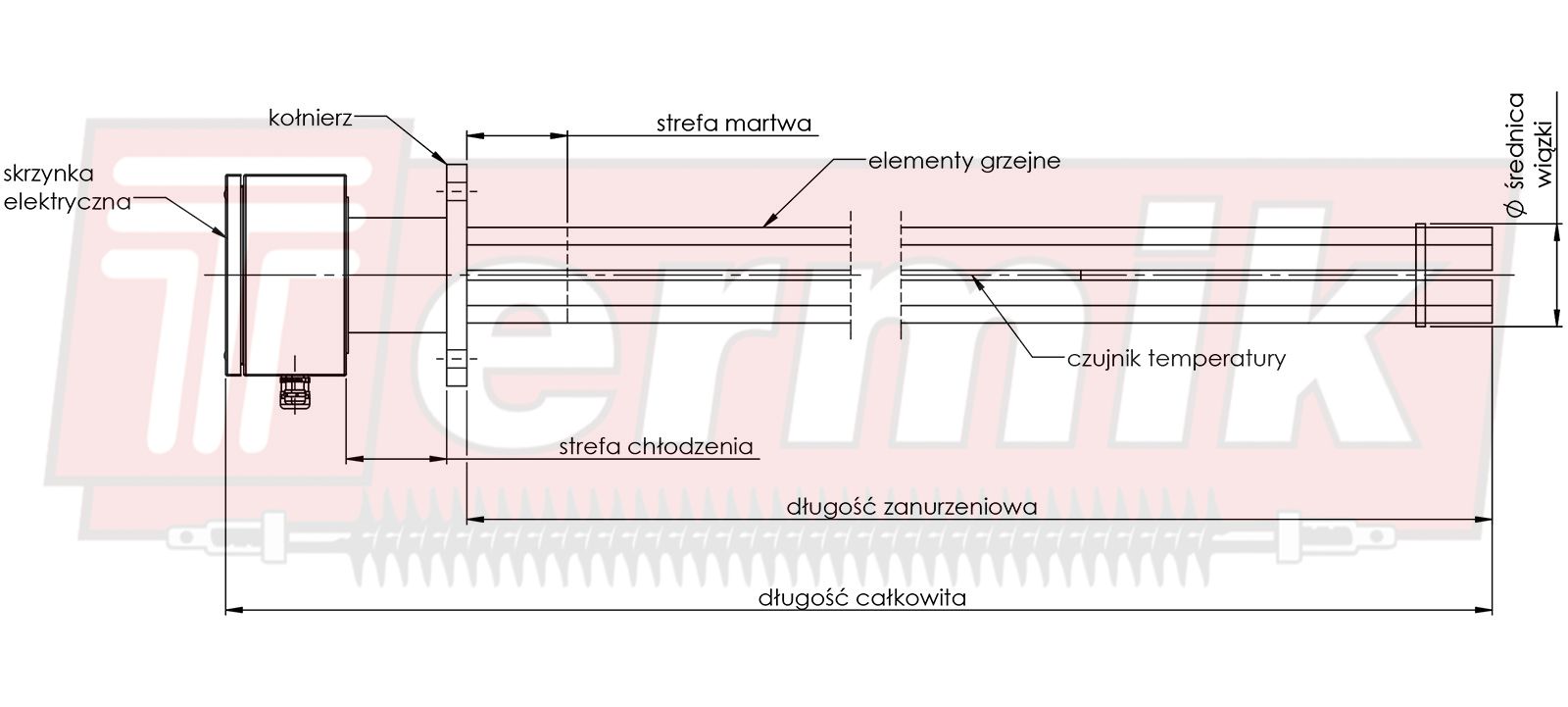

Flanged Heating Units are used for the direct heating of liquid and gaseous fluids. The design of the heaters is based on general conditions such as the type and properties of the fluid, temperature, pressure, etc. The units are made of tubular or ceramic heaters enclosed in protective casings, which are welded to the flange. They are completed with a control box with an IP54 or IP65 protection rating.

Application:

Specification

| 1. Tubular Heaters | |

|---|---|

| Diameter | 8,5mm/10,0mm/12,0mm/16,0mm |

| Material | 1.4404, 1.4571, 1.4828, 1.4876, 2.4858 |

| Immersion length | max. 2600mm |

| Shape | “U” shape |

| Electrical connection | M4-M6 |

| 2. Replaceable Heating Elements | |

|---|---|

| Insert diameter with casing | 19,0mm – 63,5mm |

| Insert material | technical ceramic |

| Casing material | stainless steel |

| Casing immersion length | max. 2100mm |

| Shape | straight |

| Electrical connection | M4-M6 |

| 3. Thread | |

|---|---|

| Thread material | stainless steel |

| Dimensions | G1 1/2” – SW60; G2” – SW70, G2 1/2” – SW85 |

| 4. Flange | |

|---|---|

| Type | Standard (according to DIN/ANSI), custom design |

| Material | boiler steel; 1.4301; 1.4404; 1.4541; 1.4571 |

| Diameter | to be agreed upon |

| Flange pressure | to be agreed upon |

Control / Regulation

Flanged Heating Units can be equipped with a built-in control system (for low power) or a separate external control cabinet. The heating power can be divided into one or more heating sections.

A. Temperature Controllers:

- Electronic ON/OFF control

- Thyristors

- Thermostats with capillary

B. Sensors:

- PT100

- Temperature limiter with capillary

- Other thermocouples