Description:

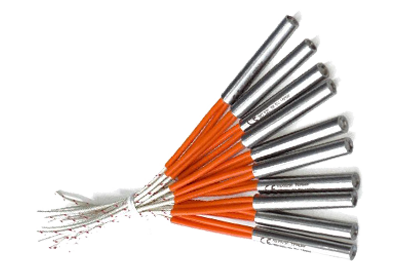

Cartridge heaters are specially designed components that allow the emission of a large amount of heat from a small surface area (max. load 30W/cm²). They are most commonly used for heating metal molds, tooling, and similar applications. These elements are designed to work in harsh conditions such as vibrations, shocks, humidity, heavy liquids, and frequent overloads. They are typically used in environments where the required operating temperature is in the range up to 550℃ (750℃ – optional).

Technical data

| Technical Data | |

|---|---|

| Surface Load Capacity | Up to 30W/cm2 |

| Power [W] | Depends on diameter |

| Leakage Current | <= 0.1mA up to 242V |

| Insulation | min. 5 MOhm/500V |

| Voltage Strength | 1500V/1sek. |

| Maximum Operating Temperature | 550°C (750°C – optional) |

| Length Tolerance | +/-1.5% |

| Diameter Tolerance | H7 (from -0.02 to -0.06mm) |

| Power Tolerance | +5% -10% |

| Dead Zone | Depends on length and diameter, from 5 to 15mm |

Applications

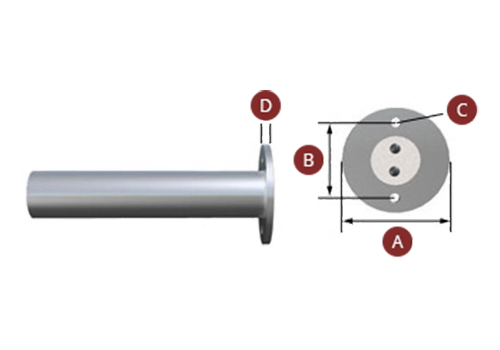

Technical drawings

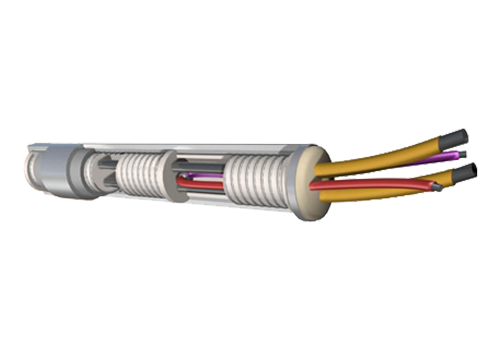

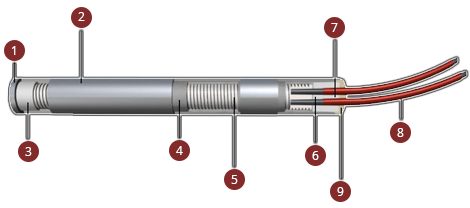

- Hermetically welded bottom (TIG). Strength up to 60kg/cm2

- Heater housing made of stainless steel AISI 304, 321, Incoloy 800

- Ceramic disc (insulator)

- Pure magnesium oxide

- NiCr8020 winding

- Ceramic core

- Hard ceramic head

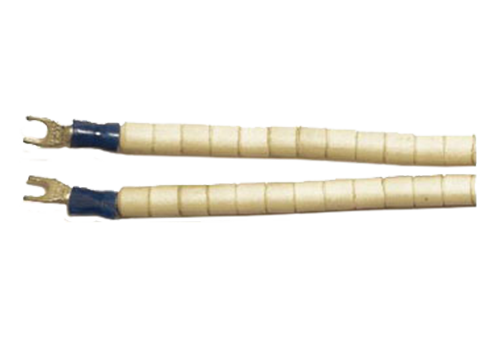

- High-temperature connection wires

- Additional hardening paste

The unique production system at Termik ensures perfectly precise winding, and together with the electronic system for measuring the spacing between the coils of the spiral, it guarantees an even temperature distribution along the entire length of the cartridge heater.