Technology

Tubular heating elements are made according to the KANTHAL - OAKLEY technology on the latest patents and solutions in machines and devices from CSM and Kanthal / Granlund. High-quality materials are used for high durability and reliability of work: magnesium oxide, high-class resistance wires and a shroud tube according to specific standards for the heating industry. Electric heating elements manufactured by us meet the requirements of DIN EN 60335-1 (VDE-700-1), have certificates entitling to mark "CE" and "VDE".

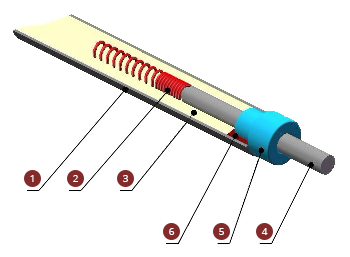

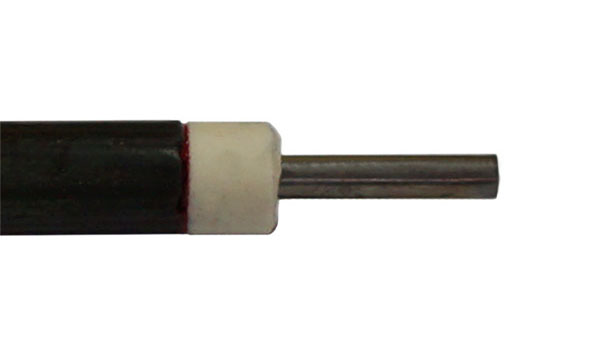

Construction of a tubular heating element

- Tube

- Resistance Coil

- Magnesium oxide

- Terminal pin

- Ceramic insulator

- Sealing

Lengths of tubular heating elements

| The material of the tube | Diameter of the heating element | ||||

| 6,4mm | 8,5mm | 10mm | 12mm | 16mm | |

| Stainless steel | 200-3350 | 200-4900 | 250-5200 | 250-5200 | 250-6000 |

Tolerance of the diameter of the heating element:

- ±0,1mm for diameters 6,4-10,0mm,

- ±0,2mm for diameters 12,0-16,0mm.

Tolerance of the length of the heating element:

- ±1,5%,

- on special request ±2mm.

VOLTAGE AND RATING POWER

The range of applied voltages: 12V...480V.

Typical used voltages: 24V, 48V, 115V, 230V, 400V, 440V.

The power of the heating element is individually selected depending on the working conditions and length.

The power tolerance in accordance with DIN EN 60335-1 is + 5% -10%. On special ±5%.

Lengths of standard dead zones: 40 / 60 / 80 / 100 / 120 / 150 / 180 / 200 ... 1000mm.

Table of used materials

| EN | AISI | Max. Temp. work material |

| 1.4301 | 304 | 550°C |

| 1.4541 | 321 | 650°C |

| 1.4404 | 316L | 450°C |

| 1.4571 | 316Ti | 500°C |

| 1.4828 | 309 | 900°C |

| 1.4876 | Incoloy 800 | 1050°C |

| 2.4858 | Incoloy 825 | 1100°C |

CHOICE AND APPLICATION OF TUBULAR HEATING ELEMENTS

When selecting a heating element, it is necessary to specify the following parameters:

- application

- working temperature

- heated medium (gas, liquid, steel form, etc.)

- external dimensions, shape

- power, voltage

- type of attachment and connection

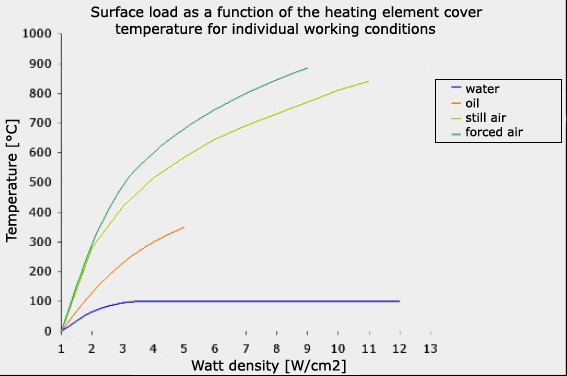

When choosing power, account should be taken of the permissible maximum carrying capacity depending on the operating conditions:

| Working environment | Material | ||

| AISI 316L, 316Ti, 321 | Incoloy 800, 825 | ||

| Stagnant water | 10 | ||

| motion water | 14 | ||

| flowing water | 25 | ||

| Steam generators | 6 | ||

| thin oil | 3,5 | ||

| thick oil | 1,2 | ||

| still air | 5 | 6 | |

| Forced air 3m/s | 6 | 7 | |

| Forced air 9m/s | 9 | 9 | |

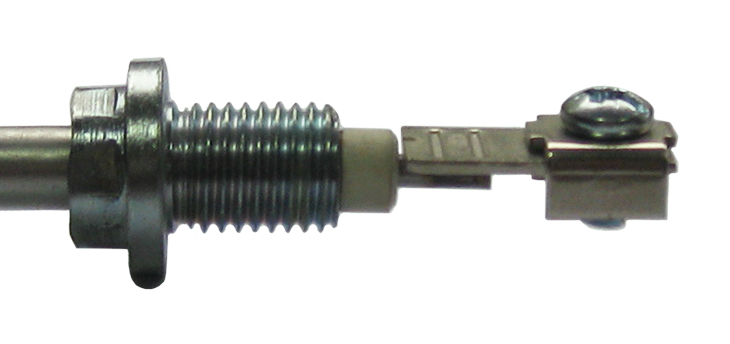

FIXING OF HEATING ELEMENTS

To mount a single tubular heating element, we use fastening bush that ensure safe and secure assembly in the workplace.

Currently, the offer includes over one hundred different types of fastening bushes. We also make fastenings strictly to the customer's order.

| Bushes | |

| Material | Plain steel, galvanized, brass, AISI 303, AISI 304 |

| Thread | M10x1, M12x1,25 , M14x1,5 , M16x1,5 , M18x1,5 , M20x1,5, M24x1,5 |

| assembly method | Crimping, Brazing |

When mounting several individual heating elements close to each other, we normally use clamping heads / flanges with a specified thread.

These provide easier assembly and better functionality (including electrical connection).

| Heads, Mounting flanges | |

| Material | Brass, stainless steel AISI 304, AISI 316L (on request), plain steel ST |

| Thread | G1" - G2 1/2" |

| assembly method | Brazing 45Ag (on request 56Ag) |

Depending on the size of the head / flange, you can put up to 6 individual heating elements at a time.

An additional way of fixing the heating elements are made to order special fixing plates, round flanges (Dmax = 500mm), rectangular (max 600x400mm), square (up to 400x400mm), casing pipes, etc ...

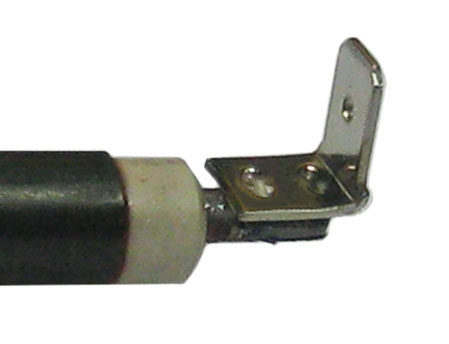

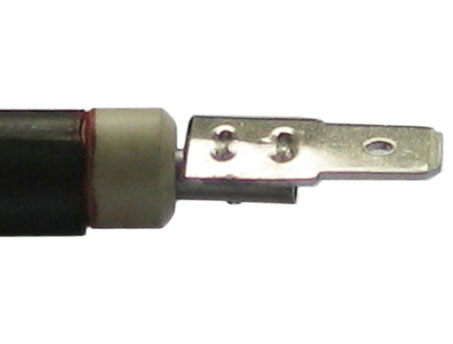

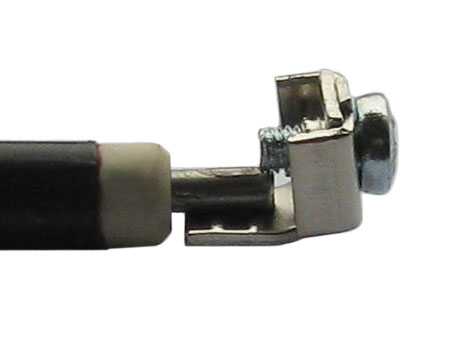

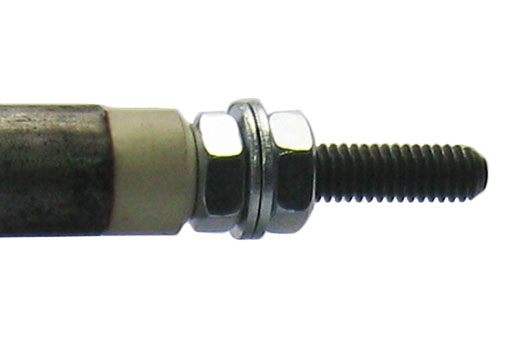

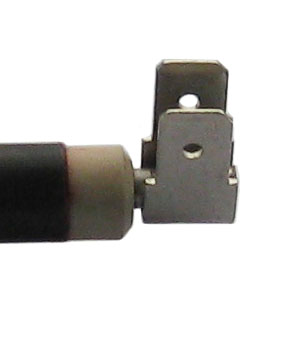

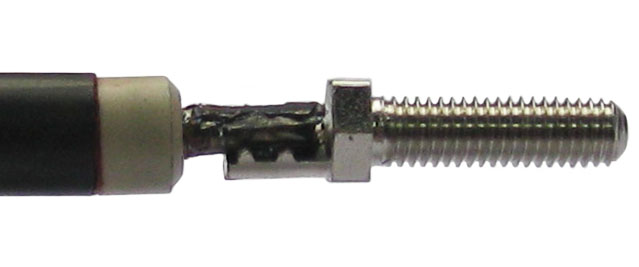

Current outputs

For tubular heating elements, we use the following current outputs:

C18,5/6,4

Flat connector M4

C28,5/6,4

Faston 6,3 angular 90°

C38,5/6,4

Faston 6,3 straight

C48,5/6,4

Faston 6,3 angular 45°

C58,5/6,4

Sealed terminal pin

C68,5/6,4

Angular connector M4

C78,5

Thread M4 + nut

C86,4

Double faston 6,3 angular

C96,4

Double faston 6,3 straight

C108,5

Welded Terminal M4, M5, M6

C118,5/6,4

Isolated cable

C128,5

Hermetic sealing

-->